The art of bread-making is as much a science as it is a craft, and at the heart of this process lies a seemingly simple yet profoundly important phenomenon: dough fermentation. While bakers often focus on ingredients like flour, water, and yeast, it is the invisible gas—carbon dioxide—that plays the starring role in transforming dense, sticky dough into light, airy bread. This silent protagonist works behind the scenes, creating the texture, volume, and flavor that define great bread. Understanding the relationship between dough fermentation and carbon dioxide is essential for both professional bakers and home enthusiasts alike.

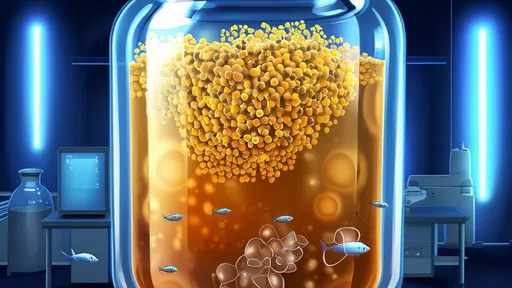

When yeast is introduced to dough, it begins to consume sugars present in the flour, producing carbon dioxide and alcohol as byproducts. This biochemical process, known as alcoholic fermentation, is what causes the dough to rise. The carbon dioxide gas gets trapped within the elastic network of gluten, forming tiny bubbles that expand as fermentation progresses. The longer the dough is allowed to ferment, the more gas is produced, and the more complex the flavors become. This is why slow fermentation, often referred to as cold fermentation, is prized in artisanal baking—it allows for greater gas retention and a more developed taste profile.

The temperature at which dough ferments significantly impacts carbon dioxide production. Warmer environments accelerate yeast activity, leading to faster gas generation but potentially weaker gluten structure. Conversely, cooler temperatures slow down fermentation, giving the gluten more time to strengthen while still allowing for steady gas accumulation. Bakers must strike a delicate balance between these factors to achieve optimal rise and texture. A well-fermented dough will exhibit a smooth, slightly domed surface with visible gas pockets when gently stretched—a testament to the carbon dioxide at work.

Beyond texture, carbon dioxide also influences the flavor of bread. As fermentation progresses, the gas interacts with other compounds in the dough, contributing to the development of nuanced tastes and aromas. The slight tang of sourdough, for instance, arises from prolonged fermentation where carbon dioxide and organic acids work in tandem. Even in quick-rise commercial breads, the presence of carbon dioxide is what delivers that familiar, satisfying lightness. Without this gas, bread would be little more than a dense, flavorless mass.

Modern baking techniques have introduced ways to manipulate carbon dioxide production for consistent results. Some bakers use preferments like poolish or biga to jumpstart fermentation, while others rely on controlled proofing boxes to regulate temperature and humidity. In industrial settings, dough conditioners and additives may be employed to enhance gas retention. Yet, despite these advancements, the fundamental role of carbon dioxide remains unchanged. It continues to be the driving force behind one of humanity’s oldest and most beloved foods.

For those looking to improve their bread-making skills, paying attention to dough fermentation is key. Observing how the dough responds during bulk fermentation and proofing stages can reveal much about carbon dioxide activity. A dough that doubles in volume, holds an indentation when pressed, and exhibits a network of air bubbles is on the right track. Mastering this aspect of baking unlocks the door to endless possibilities, from crusty baguettes to soft sandwich loaves—all thanks to the quiet, persistent work of carbon dioxide.

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025